Glass-Reinforced Polypropylene TME's

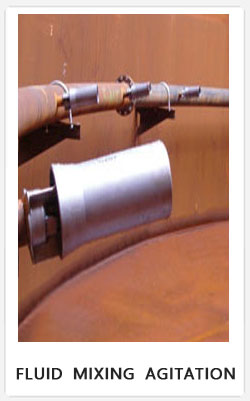

- Tank Mixing Eductors (TME’s) enable small pumps to circulate large tanks. The suction produced by the venturi action of the eductor greatly amplifies the mixing ability of the pump. Solids in the tank are kept from settling by the velocity of the discharge plume. The eductors are placed on the tank to maintain critical velocity of the solid particles. Keeping the eductor at a slight downward angle can help maintain critical velocity on the tank floor.

- TMEs can be used in conjunction with Uni-Spray Saddles or Clip-On Nozzles for easy installation.

- Eductors are moulded of Glass-Reinforced Polypropylene, with a temperature range up to 104˚C (220˚F). They are also available in brass, stainless steel or Kynar.

Major Dimensions

TME Capacities

OPERATING LIQUID FLOW (gpm) at Pressure Differential (psi)

Note: The flow rate that is shown in the above chart is the motive or throughput of the eductor. The actual discharge from the eductor is 5 times the motive.

Example: 3/8" eductor @ 10 psi motive = 7.5 discharge; 5 x 7.5 = 37.5 gpm.

- The flow rates shown below are based upon water (SG 1.00) as the motive liquid. To adjust the values for liquids with a different specific gravity, use the following formula:

[ √ (1÷SG of actual motive liquid) ] x Table Value = Flow Rate of actual motive liquid

- The pressure differential (∆P) shown in the table is the ∆P across the TME, not the pump. The ∆P equals the motive inlet pressure (Pm) minus the discharge pressure (Pd).

- The discharge pressure is the static liquid pressure in the vessel, assuming the vessel is vented to the atmosphere (see formula below). If the vessel is pressurized, the Pd is that value plus the static liquid pressure.

((Liquid Height in feet) x SG) x 0.43 = Pd

- For mixing applications, one psi of ∆P produces 6" of effective discharge plume length

Applications

Related Products